GM Machinery’s efficient paper production equipment is meant to be used for mass production so as to guarantee high-standard paper output even when produced in large quantities. Our machines are made with the latest technology which helps us improve on efficiency during production while still keeping the quality and stability of products intact. It does not matter if you are making office papers or packaging them, we have got what it takes! This means that our efficient paper production equipment can meet all your requirements. With its strong control systems and robust structural design, GM Machinery offers reliable solutions for factories looking towards cutting down their costs of operation thus becoming more competitive in the market too.

To make a paper machine GM Machinery believes in reliability and efficiency. GM Machinery leads the industry with its technological capabilities by creating advanced models for paper production and processing. Innovations from countries such as Germany or Italy are incorporated into these machines that have been designed over 30 years of experience in this field which ensure they meet all necessary standards for performance as well durability – mainly because they use only the best parts available worldwide. They always try to find new ways to improve their products through research and development so that every client can get what he needs: either an ordinary device or the most cutting-edge solution created especially for him. CE marking is used on many items produced by GM Machinery which guarantees their compliance with ISO regulations but also adds value because people trust those companies more where everything is done according to regulations invented globally like these ones about safety during work around machines.

Our commitment to relentless self-improvement and satisfying the customers fuels GM Machinery’s dominance in inventing paper machines. We have bases across different parts of the world where we manufacture goods or offer services. Our clients’ support systems are well taken care of by a range of service points and factories internationally set up. The company has professionals who take their time in listening, offering guidance from scratch through to use and even at regular checks for sustainability purposes. Trust us to give you nothing short of excellence coupled with unmatched customer service – this is what our skilled team believes in day after day as they work tirelessly towards these goals! This means that if necessary we will always be available so don’t hesitate when reaching out because your success matters too much not only for GM Machinery but also entire humanity itself; everything else can be postponed till later except helping one another succeed now!

GM Machinery bases its paper machine design on environmental sustainability. Our goal is to come up with green solutions that do less harm to the earth but still do well in terms of performance. With this in mind, we have introduced energy-saving methods into our machines such as improved drying systems or ways of minimizing waste during production among others. What this means for businesses partnered with us is that they can meet their own environmental targets while staying profitable and competitive at the same time since it will be easier now more than ever before; together we are making tomorrow’s papers today’s news through ecology!

GM Machinery is continuously developing our designs to meet the changing demands of the paper machine industry, and thus we are a pioneer in this field. Our dedication to new ideas means that we create advanced systems which save time, money and energy throughout paper production. We do this by incorporating current materials and methods into our process; as a result customers can expect better reliability from their GM Machinery purchased paper machines along with higher performance levels achieved at lower costs worldwide. No matter whether you operate on a smaller scale or have an expansive facility – our equipment is designed specifically for optimizing production efficiencies while attaining operational greatness.

Zhengzhou Guangmao Machinery Manufacture Co. LTD, based in Zhongyuan District, Zhengzhou, specializes in manufacturing paper making and processing machines. With over 30 years of experience and technology imported from Germany and Italy, they offer a range of advanced products. They provide OEM and design services, boasting CE and ISO certifications. Their commitment to quality and customer satisfaction is evident through partnerships with over 25 countries, ensuring a strong global reputation for excellent products and service.

Efficient molding process for eco-friendly packaging.

High-speed production with excellent strength-to-weight ratio.

Produces strong, recyclable paper for versatile packaging solutions.

Delivers soft, absorbent tissue rolls for premium hygiene.

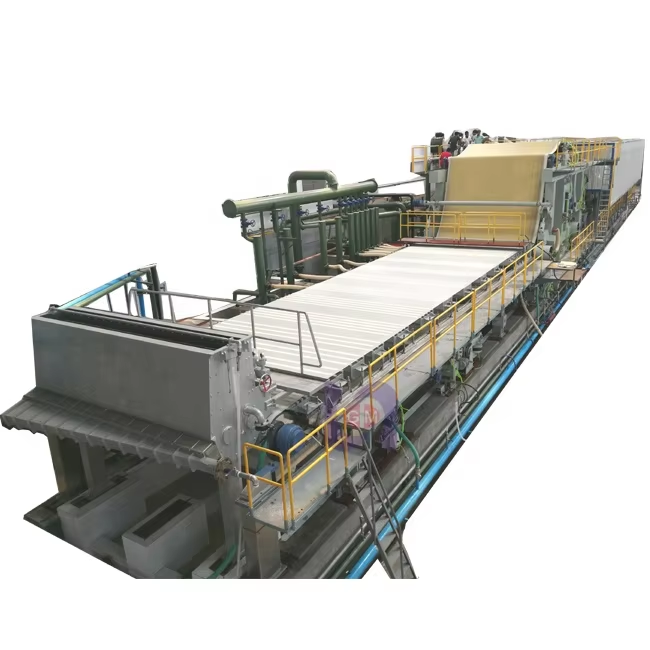

Our company specializes in a range of paper machines including Fourdrinier, twin-wire former, and cylinder machines. Each type is designed to meet specific production needs and quality requirements in the paper manufacturing industry.

When selecting a paper machine, important factors include production capacity, paper type versatility, energy efficiency, maintenance requirements, and initial investment cost. Our experts can guide you through selecting the optimal machine based on your production goals and operational preferences.

Our paper machines are engineered with advanced technology to enhance production efficiency. Features such as automated controls, precision engineering, and high-speed capabilities contribute to reducing downtime, minimizing waste, and increasing overall output, ensuring a more efficient production process.

We offer comprehensive after-sales support including installation, training, maintenance services, and spare parts availability. Our service team is committed to ensuring your paper machine operates at peak performance throughout its lifecycle, maximizing your investment's value.

Yes, we understand that every paper manufacturing operation is unique. Our engineering team can tailor our machines to meet specific production needs, whether it involves adjusting capacity, accommodating different paper grades, or integrating specialized features. We prioritize delivering solutions that align with your exact requirements.