The GM Machinery high-capacity corrugated paper machine is designed using state of the art technology and a dependable configuration to match bulk production requirements. This machine produces high quality corrugated papers with efficiency and precision that are widely used in the packing industry. Its control system automation ensures effective running by reducing manual involvement which cuts down on the cost of production. What this offer from GM Machinery does is not only improve efficiency levels in manufacturing but also meets customers’ needs for good packaging materials while giving them a reliable solution for their production demands. Whether you operate as a packaging company or a supplier of papers, this strategic partner will help you realize continuous growth in your business; it’s none other than the GM machinery large capacity corrugated paper machine.

The optimistic way in which GM Machinery approaches the creation of fluting paper machines is through quality assurance. In order to achieve and maintain high standards for performance as well as durability, every machine is tested and checked extensively. They also guarantee that their equipment will last longer by using only top quality materials during production. At each stage from design until completion this company ensures excellence by paying attention to details which others may overlook; such commitment can be seen when they go beyond what customers expect from them because all their fluting paper machines must either meet or surpass these expectations according to GM Machinery’s quality policy. Manufacturers need reliable machinery that works consistently well over time so it helps them succeed with operations – this is why manufacturers rely on g mma chinery.

GM Machinery is recognized as a pioneer in the production of fluting paper machines that are known for being inventive and dependable. These types of machines are made to manufacture high quality fluting papers which are required in the production of corrugated cardboards. GM Machinery incorporates modern technologies into their models so as to achieve maximum efficiency and performance. The reason why GM Machinery succeeds in producing these kinds of outcomes is because they pay attention to accurate engineering coupled with strong structures during construction stages for their fluting paper machines which enable them deliver consistent results according to international standards demanded by paper mills globally. Manufacturers rely on GM machinery because their equipment helps increase output without compromising product excellence.

Worldwide, GM Machinery guarantees maximum uptime and operational efficiency for customers who use fluting paper machines by giving them support which is very important. From installation and commissioning through ongoing maintenance and troubleshooting, their network of service centers staffed with knowledgeable technicians provide timely help to manufacturers. To ensure the best performance of machines possible, training programs as well as technical consults are offered by them which may explain why they have such a good name for themselves in this industry.

So as to meet the unique requirements of paper mills, fluting paper machines can be customized by GM Machinery in many ways. They know that all production environments are different and because of this they work closely with their clients during every step of the process in order to modify machine specifications such as capacity, width and level of automation among others. Manufacturers are able to optimize their production processes effectively while at the same time being flexible enough so that they can adapt quickly to any shifts in market demands according to this statement. Another thing about GM machinery is that it ensures integration of its fluting papers into current systems which leads to increased productivity throughout an organization since it enhances efficiency as well.

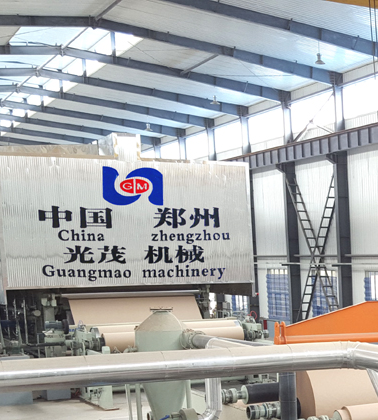

Zhengzhou Guangmao Machinery Manufacture Co. LTD, based in Zhongyuan District, Zhengzhou, specializes in manufacturing paper making and processing machines. With over 30 years of experience and technology imported from Germany and Italy, they offer a range of advanced products. They provide OEM and design services, boasting CE and ISO certifications. Their commitment to quality and customer satisfaction is evident through partnerships with over 25 countries, ensuring a strong global reputation for excellent products and service.

Efficient molding process for eco-friendly packaging.

High-speed production with excellent strength-to-weight ratio.

Produces strong, recyclable paper for versatile packaging solutions.

Delivers soft, absorbent tissue rolls for premium hygiene.

We offer a variety of fluting paper machines including medium consistency and high consistency models. These machines are designed to meet different production capacities and quality requirements for manufacturing fluting paper used in packaging.

Our machines are equipped with advanced control systems for precise regulation of pulp consistency, refining, and sheet formation processes. This ensures uniformity in paper thickness, strength, and surface properties, meeting stringent quality standards for packaging applications.

Our machines feature state-of-the-art headboxes for uniform pulp distribution, advanced drying systems for efficient moisture removal, and online monitoring systems for real-time quality control. They are designed for high-speed operation and reliability, optimizing production efficiency.

To maximize efficiency, we recommend regular maintenance and calibration of machine components. Our machines are engineered for minimal downtime with quick-change capabilities for rolls and screens, ensuring continuous operation and maximum output.

We provide comprehensive support including installation, operator training, and technical assistance. Our service team offers preventive maintenance programs, spare parts availability, and remote diagnostics to support your production needs and maintain peak performance of your fluting paper machine.