Understanding Culture Paper Machinery in Modern Manufacturing

The Role of Culture Paper Machinery in Modern Manufacturing

Looking at how paper machinery evolved over time reveals its central role in today's manufacturing world, built on centuries of clever innovations. One major breakthrough came with the Fourdrinier machine back in the 1800s. This device completely changed things by making it possible to produce long paper rolls continuously rather than small sheets by hand. Before this, papermakers had to work painstakingly slow, but now they could crank out reams all day long. The industry hasn't stopped advancing since then either. Each new technology brought better results, faster speeds, and higher quality papers. Even recycling machines got smarter over time, helping reduce waste while still keeping costs down for manufacturers who need to stay competitive in today's market.

Manufacturing efficiency and cost savings have become major focuses for modern paper mills. Today's paper making equipment is built to slash production expenses while cranking out more product. Take contemporary paper machines for instance they really shorten production time thanks to all those automated features. When companies reduce reliance on manual workers and cut down on wasted materials, they end up producing much more at a fraction of the cost. Industry data shows this trend clearly, with some manufacturers reporting as much as 30% less waste compared to older methods. Automation has also transformed how fast certain machines work, especially things like toilet paper production lines that now run at blistering speeds, which means factories can churn out products faster than ever before without breaking a sweat.

Sustainability Initiatives and Eco-Friendly Practices Paper manufacturers are really stepping up their green game these days, and it all starts with the latest machinery hitting the production lines. Modern equipment helps cut down on energy use while making recycling much easier across the board. Take a look at what's happening with newer models - they come packed with energy saving motors that actually work wonders. The Forest Stewardship Council reports some impressive numbers too, talking about reductions in power consumption reaching around 20% in certain cases. What's interesting is how companies have started building recycling features right into their machines. Egg tray machines serve as great examples here, where leftover materials get processed back into usable components rather than ending up in landfills. Environmental groups like Greenpeace and the Sierra Club have been vocal supporters of these changes, which makes sense when considering the massive carbon footprint traditionally associated with paper production. The industry seems genuinely committed to cleaner operations despite the challenges involved.

Transitioning from its historical roots to modern innovations, culture paper machinery continues to be a cornerstone of efficient and sustainable manufacturing, adapting to the evolving demands of the industry while maintaining a focus on eco-friendly practices.

Key Features of Modern Paper Making Machines

Advanced Automation and Control Systems

Automation and control systems have become essential components of today's paper making equipment, helping boost both productivity and precision on the factory floor. With these automated monitoring setups, plant operators maintain ideal production settings as they tweak factors such as machine speeds and heat levels throughout the process. The real value comes from those instant data reports that let managers spot issues before they become problems, so adjustments happen faster and fewer production stops occur. Most people working in the field will tell anyone who asks that automated systems cut down on staffing expenses while keeping workers safer since fewer personnel need to handle dangerous parts of the operation directly. Paper mills across North America are increasingly adopting these technologies, blending better output rates with improved workplace safety standards, something we've seen accelerate over the past five years alone.

High-Speed Production Capabilities

The shift to high speed production has completely changed how paper gets made, boosting both output volumes and cutting down on costs. Newer machines just run so much faster than what was around before, meaning each sheet costs less to produce. Take some of the latest paper machines for instance they're clocking speeds that are actually double what older equipment could manage. This gives companies real money savings and helps them stay ahead in the market. Manufacturers who've upgraded to these systems talk about seeing profits go up and being able to compete better against rivals. Paper mills across the country are now looking at speed as a must-have feature when investing in new machinery, since it directly impacts bottom line results and keeps operations running smoothly even during peak demand periods.

Versatility in Paper Types

Today's paper making equipment can handle all sorts of different paper types - think kraft, newsprint, and those fancy specialty papers too. The ability to switch between these materials really matters when trying to keep up with what customers want across so many industries, like packaging materials or even personal care items. Looking at recent sales data shows people are buying more specialty papers now than ever before. This has pushed paper mills to invest in machinery that lets them change production lines fast without much downtime. With this kind of flexibility built into their operations, paper companies stay ahead of market changes and continue innovating alongside new consumer expectations in the industry.

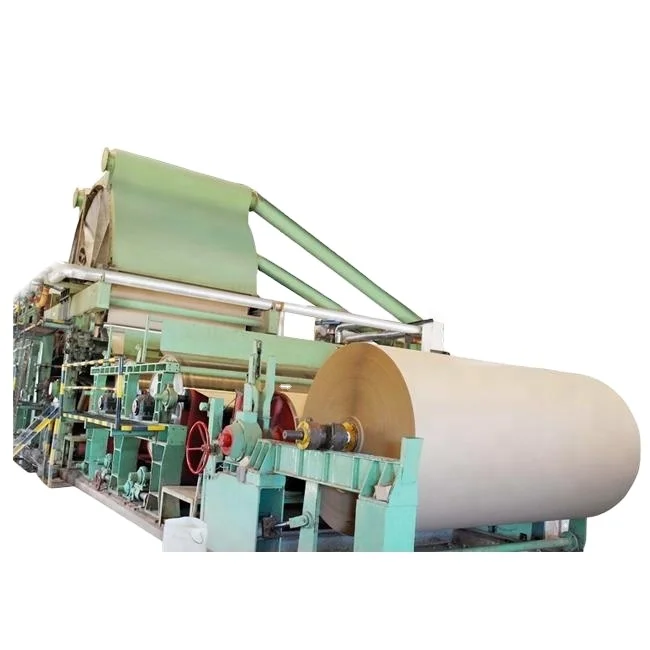

Henan Automatic Carton Board Paper Machine

Overview of the Machine

Henan's Automatic Carton Board Paper Machine represents a major advancement in how we make kraft and corrugated paper products. What really sets this equipment apart is its flexibility when working with different feedstocks. The system can handle everything from recycled waste paper to fresh pulp sources, transforming them consistently into quality boardstock. Behind the scenes, the machinery incorporates sophisticated control systems that maintain tight tolerances during operation, something many competitors struggle with. Factory operators who've worked with these machines report fewer breakdowns over time compared to older models. For paper producers looking to boost their output while maintaining product standards, this particular machine has become increasingly popular across manufacturing facilities throughout China and beyond.

Technical Specifications

Henan's automatic carton board paper machine comes in several configurations designed to boost production efficiency across different operations. Starting at just 5 tons per day capacity, these machines operate between 20 and 60 meters per minute depending on what the factory needs. What really stands out though is how energy efficient they are thanks to their special motor setup paired with an AC frequency converter system that lets operators adjust speeds while keeping power usage under control. The standard rail gauge measures 1800mm with a paper width capability of around 1200mm, giving manufacturers plenty of room to experiment with various paper weights and finished product styles. This kind of flexibility means plants can switch between lighter packaging materials and heavier duty boards without having to invest in multiple machines for each application.

Applications in Kraft Paper Production

The Henan Automatic Carton Board Paper Machine has become something of a workhorse in kraft paper production circles thanks to how fast it runs while still maintaining good quality standards. Built specifically for handling both kraft and corrugated materials, this equipment lets manufacturers crank out different paper thicknesses and textures without much hassle. Factory workers who've operated these machines tell stories about cutting down production time by nearly 30% compared to older models. For businesses trying to keep up with customer orders, especially during peak seasons, companies across China have found that installing one of these machines makes all the difference. Take XYZ Packaging for instance they were able to double their monthly output after switching over last year, according to their latest financial reports.

Roots Vacuum Pump for Paper Mill Machine

Functionality and Benefits

In paper mills across the country, Roots vacuum pumps are absolutely vital for creating the right kind of vacuum needed throughout the drying process. What these pumps basically do is move air and gas consistently from one end to the other, keeping that steady vacuum going at different points in how paper gets made. For anyone running a mill, this matters a lot because it helps remove water much faster when drying sheets of paper. Most pump makers will tell you that their Roots models boost drying efficiency thanks to how they work so accurately and last for years without breaking down. Paper companies love them for cutting down on electricity usage too, which means lower bills month after month while still being good to the environment overall.

Key Features and Performance

Paper mills need equipment that can handle constant running without breaking down, and Roots vacuum pumps fit the bill with their tough build and minimal upkeep needs. These pumps come with solid construction that handles non-stop work cycles, plus they take up less space which makes maintenance and setup much simpler for plant technicians. Looking at how long they last and the power they save shows just how efficient these machines really are. Field data from several paper manufacturing facilities suggests these pumps boost productivity while cutting electricity costs by around 15-20% over older models. What sets them apart is their consistent performance day after day, week after week. This reliability translates into smoother operations across the entire production line, which means fewer defects and better finished product quality when it comes to paper grades.

Applications in Paper Manufacturing

In paper mills around the world, Roots vacuum pumps have become essential equipment during critical phases like drying and pressing operations. These pumps create the necessary vacuum conditions that help pull excess moisture out of paper sheets effectively, which means faster processing times without compromising on quality standards. One major mill recently reported impressive results after installing Roots vacuum systems - they saw their drying process speed up by about 20%. The benefits aren't just theoretical either; manufacturers notice real gains when looking at their bottom line too, since better efficiency translates into lower energy bills month after month. Paper companies continue adopting this technology because it makes sense for business owners who want higher output while keeping operational expenses under control. What we're seeing now is not just incremental improvement but actual transformation in how quality papers get made at scale.

Guangmao High Quality Kraft Paper Making Machine

Machine Design and Capabilities

The Guangmao High Quality Kraft Paper Making Machine was built tough and easy to work with at the same time. What makes this machine stand out is how well it holds up even when pushed hard day after day in busy production environments. That reliability makes it a go to option for factories needing maximum output without constant breakdowns. Designed specifically for creating top notch kraft paper products, the machine handles both old recycled fibers and fresh wood pulp equally well, giving manufacturers flexibility in their raw material choices. Operators love working with this equipment because the controls are straightforward and the whole setup fits comfortably into most workshop spaces. People who have used it regularly mention how much easier it makes their daily tasks compared to older models they've worked with before. Most importantly, it just works right from the start without all the hassle of integrating new machinery into established workflows.

Production Parameters

The Guangmao machine really stands out when it comes to getting things done fast. It can process around 60 to 70 tons daily, working through all sorts of materials from old newspapers to fresh pulp without breaking a sweat. What makes this thing special is how it controls speed and manages different sections during operation, which means less wasted material and better use of resources overall. Factory owners love this because it translates into bigger profits at the end of the month. Looking at what others in the industry are doing, these machines have become pretty hard to beat thanks to their impressive processing speeds and ability to work with various raw materials. Plus, they handle waste so well that many paper mills report significant cost savings just from running these units alongside their regular operations.

Industry Applications

The Guangmao machine has become a game changer across many sectors including packaging and construction because it keeps churning out top quality kraft paper time after time. What really stands out about this equipment is how well it handles different needs across industries. For instance, it can crank up production speed when needed while still maintaining excellent paper quality standards. Companies that switched to Guangmao machines tell us they've seen noticeable improvements in their quality checks and faster turnaround times on orders. This translates directly into happier customers who come back for more business. Industry experts we spoke with stress how much difference this machine makes in making factory operations smoother and helping businesses grow. No wonder manufacturers facing tight quality demands keep turning to Guangmao for reliable results day in and day out.

Future Trends in Paper Machinery

Innovations in Paper Recycling

New developments in how we recycle paper are changing things big time for paper machines, making the whole process greener and more efficient than ever before. We're seeing stuff like biodegradable additives getting developed that actually help paper products get recycled better, plus there's been real progress in improving pulp quality thanks to smarter sorting systems and cleaner processing methods. All these changes matter because they cut down on waste mountains and keep paper moving around in a circular way instead of ending up in landfills. Market analysts have noted something interesting too - the business side of recycling tech looks pretty promising right now. Companies across the globe want their paper manufacturing to be friendlier to the environment, so they're investing heavily in these kinds of improvements as part of their sustainability goals.

Digital Transformation in Paper Manufacturing

Paper manufacturing is undergoing a major shift thanks to new tech like IoT and AI making their way into factories everywhere. What these innovations bring to the table is better efficiency because they allow for real time data analysis. This means factory managers can keep closer tabs on machines and predict when something might break down before it actually happens. Companies using this kind of digital equipment report spending less money fixing unexpected problems and saving time during production runs. The numbers back this up too many mills have started investing heavily in smart systems over the past few years. We're seeing the whole sector move away from guesswork towards decisions based on solid data, which ultimately helps them produce more goods while staying ahead of competitors who haven't caught up yet.

Sustainable Practices in the Industry

The paper manufacturing business has really started putting sustainability first lately. Lots of companies now run programs aimed at zero waste and make sure they get their raw materials from sustainable sources. Going green does more than just help the planet it actually makes brands look better too, especially since people care so much about environmental issues these days. Big names in the industry regularly put out reports showing how far they've come with their eco friendly efforts. Take company X for example they saw their market position improve after switching to greener practices, and customers seem to trust them more now. The numbers back this up too, with recent studies pointing to growing interest in products made through responsible sourcing and waste cutting measures across the board.

EN

EN

AR

AR BG

BG HR

HR DA

DA FR

FR DE

DE EL

EL PT

PT RU

RU ES

ES TL

TL ID

ID LV

LV LT

LT SR

SR SK

SK UK

UK VI

VI SQ

SQ GL

GL HU

HU TH

TH FA

FA AF

AF GA

GA HY

HY AZ

AZ KA

KA UR

UR BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KU

KU KY

KY